Nowadays, the market competition is intensifying, the product quality requirements are becoming higher and higher, domestic plastic enterprises are like other enterprises.

The general market causes some enterprises to enter the high-end market or do export business; but the increase of product quality. Affect the quality of the one link: cutting is particularly important.

Ordinary quality requirements are not high cutting generally will be a little edge, how to improve the smoothness of the cutting edge is the problem we must solve to improve the quality of plastic absorption products. Do the following two major items can improve the smoothness of the plastic absorption edge:

1. A knife mold made with imported blades

In order to improve the smoothness, sharp and super hard knife molds are essential (generally with Japanese blades).

2. Use a steel plate instead of the PP plate

Cancel the original PP board or nylon board, replace with steel plate (general stainless steel plate can be) and require the steel plate plane.

After the completion of the above two items, it can basically solve the problem of plastic suction wool edge, but at the same time, it will bring a new problem. When the above two items are finished, the requirements of the cutting machine are more demanding

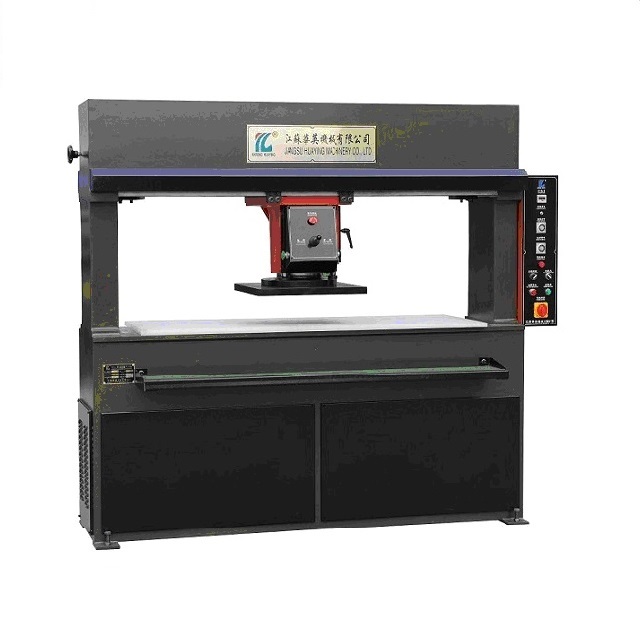

How to solve the slow return of the cutting press machine

The slow return journey of the cutting machine refers to the slow rise speed after the completion of the cutting, sometimes accompanied by large noise.

There are several reasons for the slow return trip of the cutter machine:

1. The hydraulic oil is too dirty and the filter is blocked

Nearly 70% of the slow return of the cutting machine is caused by the dirty hydraulic oil and the filter blockage. Generally, the hydraulic oil needs to be replaced once a year, and the filter should be cleaned once every three months (replaced in time). When the cutting machine is used badly, the time period of oil change and filter cleaning should be shortened.

2. The oil pump is either empty or damaged

There are two reasons why the oil pump is too little hydraulic oil and its own suction. When the hydraulic oil is less, it can be added appropriately (not to exceed the filter). If the oil pump is empty, please check whether the internal seal is damaged, if so, please replace it in time. It should be noted that the oil pump also has a service life, some oil pump empty need to be replaced with a new oil pump to solve the problem.

3. The Solenoid valve is jammed

Solenoid valve stuck is generally caused by the hydraulic oil is too dirty (their use for a long time will have wear stuck phenomenon), the solenoid valve stuck caused by the valve core is not in place so that the oil volume becomes small. Affect the return trip speed. Solenoid valve stuck is generally directly replaced solenoid valve to solve.

Post time: May-25-2025